Beschreibung

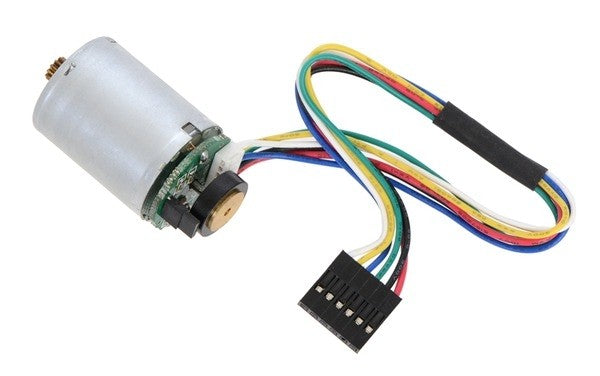

Dies ist der Motor- und Encoderteil des leistungsstarken (HP) 6-V-Metallgetriebemotoren mit 25 mm Durchmesser und 48-CPR-Encodern. Er enthält kein Getriebe, aber das Ritzel auf der Abtriebswelle ist mit allen Pololu 25-mm-Getriebemotor-Getrieben kompatibel, sodass er als Ersatzmotor oder Encoder für diese Getriebe verwendet werden kann.

Wichtige Spezifikationen bei 6 V: 10.000 U/min und 275 mA ohne Last, 0,35 kg-cm und 0,67 A bei Blockierung.

Spezifikationen:

- Größe: 24,2 D x 43 L mm

- Gewicht: 60 g

- Übersetzungsverhältnis: 1:12

- Leerlaufdrehzahl bei 6 V: 10000 U/min

- Leerlaufstrom bei 6 V: 275 mA

- Blockierstrom bei 6 V: 6500 mA

- Blockierdrehmoment bei 6 V: 0,35 kg-cm

- Leitungslänge: 20,32 cm

- Motortyp: 6,5 A Blockierstrom bei 6 V (HP 6 V)

- Encoder: Ja

Verschlüsselte Zahlung

Ihre Zahlungsinformationen werden sicher verarbeitet. Wir speichern keine Kreditkartendaten und haben auch keinen Zugang zu Ihren Kreditkartendaten.

Zolltarifnummer:

Herkunftsland:

Das hängt davon ab, wo Sie sich befinden. Nach Übergabe der Bestellung an UPS beträgt die Lieferzeit in Deutschland ca. 2-3 Tage, innerhalb Europas ca. 1 Woche.

Wir versenden unsere Artikel mit unserem Versandpartner UPS.

Wenn wir Ihre Frage noch nicht beantwortet haben, können Sie uns kontaktieren, und wir werden uns so schnell wie möglich bei Ihnen melden.